Case Story: Streamlining Shipping at 3PL withTwinPrint®

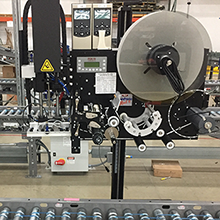

When a major 3PL sought to streamline its packing list and shipping label process as part of their plant automation, integrator Bastian Solutions recommended FOX IV Technologies' TwinPrint® dual-sided label print and apply systems, known for their reliability and efficiency.

The Challenge and Solution

Challenge

The end user desired an automated shipping label and packing slip system that could handle confidential information. They required a versatile solution for various box sizes and heights across two different fulfillment lines. The label needed to fit entirely on the smallest size box without wrapping over the edges.

Solution

FOX IV's TwinPrint® label print and apply systems were selected for their ability to print and apply 5 x 8 direct thermal over direct thermal labels, eliminating the need for thermal transfer ribbons, which carry user information as well as the products they use. This capability not only ensured confidentiality but also increased customer security by removing customer details and order information from the waste stream.

Implementation and Results

Implementation

The customer purchased four TwinPrint® systems – two for redundancy – and integrated them into their fulfillment lines. The systems utilize twin Zebra printheads, simultaneously printing shipping information on the visible top side of the label and order contents underneath on the label liner. This dual-printing process guarantees matching information, reducing mismatch errors and returns.

Each fulfillment line had specific requirements. The first line, with boxes varying in height from 1.5 to 5.5 inches, required up to 10 boxes per minute to be labeled. The second line dealt with a broader range of box sizes, from 7.125” L x 9.5” W x 4” H to 23.625” L x 21.625” W x 13.75” H, also needing to label up to 10 boxes per minute. Both systems were mounted over the fulfillment lines and utilized random height sensing to apply the labels accurately.

Results

The implementation of FOX IV’s TwinPrint® label print and apply systems not only met the customer's requirements but also enhanced the efficiency and reliability of their shipping process. This innovative solution ultimately supported their goal of achieving streamlined and automated operations, ensuring accurate and secure label application for every shipment.