Options, Accessories & Peripherals

FOX IV labeling equipment is often used in conjunction with options, accessories and periphal equipment to complete or enhance a labeling system.

Options, Accessories & Peripheral Equipment

Sometimes, you need something extra to make your labeling application a sucess, which is why FOX IV offers a variety of equipment options, accessories, and peripheral equipment. Whether you need to protect your equipment from an extreme environment, verify your barcodes, or simply print and rewind labels, we have options to help.

Additions Include:

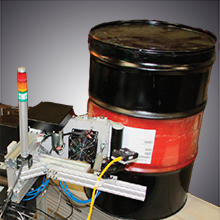

WARNING/FAULT BEACONS + ALARMS

WARNING/FAULT BEACONS + ALARMS

FOX IV utilizes a range of beacon assemblies and alarms for visible and audible alarms. Two-to-four section light beacons as well as audible alarms can alert operators to various warning or fault conditions, including low labels and machine issues. EMERGENCY STOPS

EMERGENCY STOPS

For added safety, FOX IV offers an Emergency Stop option. Emergency stops are most commonly push buttons, but other types of emergency stops can be incorporated including mats and covers with switches.  LOW LABEL SENSOR

LOW LABEL SENSOR

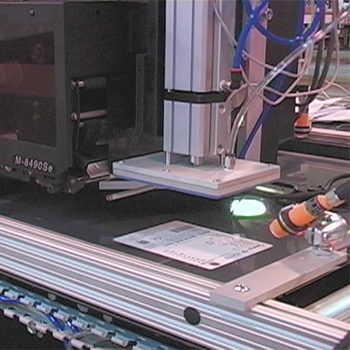

To ensure smooth operation and limited down-time, FOX IV automated labeling systems can be fit with a low label sensor. This sensor will trigger a signal (most commonly a warning light) that the label roll is getting low - enabling operators to be prepared with a new roll.  RANDOM DISTANCE SENSING

RANDOM DISTANCE SENSING

For applications where there may be different height products or products at varying distances from the applicator, FOX IV offers Random Distance Sensing. With Random Distance Sensing, the applicator accommodates the different heights/distance by slowing the applicator as it nears the product up to the maximum distance of the applicator assembly.TAMP APPLICATION

Tamp application is the most common type of application assembly. An applicator pad - either hard or soft - at the end of a cylinder assembly applies the label to the surface of the product, case, or pallet. Tamp assemblies can be either pneumatic or electric.TAMP-BLOW APPLICATION

Tamp-Blow is similar to tamp in that a cylinder assembly extends toward the surface of the product, case, or pallet; however, instead of contacting the product to apply the label, air is forced through the applicator pad to blow the label onto the surface. This is ideal for delicate or uneven application surfaces.TAMP-ROLL APPLICATION

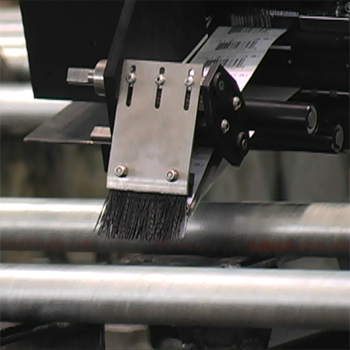

For cylindrical or soft application surfaces, or for applications that may require extra contact, tamp-roll is often used. After the label is applied with the tamp surface, a roller built into the tamp rolls over the label to firmly adhere it to the application surface.WIPE/MERGE

The wipe, also known as merge, application method utilizes an extended peel point and applicator brush to wipe the label onto a moving surface as it passes. This is popular for cylindrical products as well as higher speed labeling applications. This option does not require factory air.CUSTOM APPLICATION

If one of our standard application methods will not work for a unique application, FOX IV's in-house engineering team can design custom application methods to apply labels. T-BASED STANDS

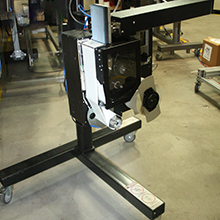

T-BASED STANDS

T-based stands are the most popular stand for our automated labeling units. The T shape enables the support leg to be positioned underneath conveyors for closer label application and higher throughput. H-BASED STANDS

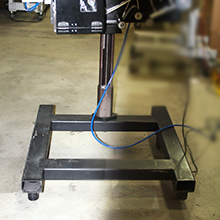

H-BASED STANDS

For heavier units or ones with a longer application stroke distance, FOX IV offers the H-Based stand. The larger base footprint provides greater stability and weight distribution than the T-Based stand.  SLIDE STAND

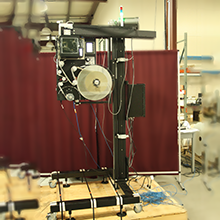

SLIDE STAND

The Slide Stand is most often utilized in systems working within a production cell, with or without robotic integration. The Slide Stand utilizes floor mounted rails to slide the labeling unit toward and away from the production line for maintenance and to change media supplies. This ensures that the unit returns to the same position each time.  MOTORIZED STANDS

MOTORIZED STANDS

Motorized stands are used for applications that may require the labeling unit to apply labels to different locations on the product, pallet, or case, depending on the particular production run. It is also used for applications where the label is applied in an area higher than an operator can reach for set up and maintenance.  CUSTOM MOUNTING

CUSTOM MOUNTING

Custom mounting stands and gantry systems can be designed by FOX IV's in-house engineering team for applications where any of our standard mounting options will not work. Custom mounting can include repositioning systems, height adjustment, extended height, and more. DUST ENCLOSURES

DUST ENCLOSURES

To protect your labeling equipment from airborne particulates and dust, FOX IV offers dust enclosures. Positive air pressure and optional sliding enclosure doors keep contaminants away from the labeling system components thereby increasing print quality, printhead life, and system up-time. WATERPROOF ENCLOSURES

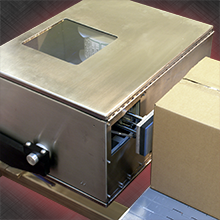

WATERPROOF ENCLOSURES

For applications in washdown environments or where splashes may occur, FOX IV recommends a waterproof enclosure. These stainless steel enclosures incoporate a sliding door to seal off the applicator assembly as well as gasket sealed access doors.  EXTREME TEMPERATURE ENCLOSURES

EXTREME TEMPERATURE ENCLOSURES

When a labeling system is in an environment that has extreme temperatures or large temperature swings, the operation of system may be compromised or the labels may refuse to peel or adhere. An Extreme Environment Enclosure minimizes temperature stress from heat or cold by incorporating a small heater or air conditioning unit as well as a sliding applicator door. CUSTOM ENCLOSURES

For enclosures for other environments, such as those requiring explosion proofing or hazardous environments, our engineering team will evaluate each application on a case by case basis. REWINDERS AND UNWINDERS FOR THERMAL PRINTERS

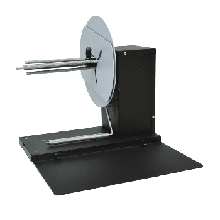

REWINDERS AND UNWINDERS FOR THERMAL PRINTERS

FOX IV offers several sizes of label rewinders and unwinders from DPR for thermal printers. Standard and heavy duty rewinders and unwinders are available for label widths up to 9.45" (240mm). These rewinders and unwinders are the perfect companion to your Zebra, SATO, or other desktop thermal label printer. REWINDERS AND UNWINDERS FOR EPSON® COLORWORKS® PRINTERS

REWINDERS AND UNWINDERS FOR EPSON® COLORWORKS® PRINTERS

FOX IV also offers label rewinders, unwinders and roll-to-roll systems for Epson® Colorworks® printers. Models for the C6000A and P, C6500 A and P, C4000 and C7500 are available. Label rolls up to 10" OD can be accommodated. LABEL DISPENSERS

LABEL DISPENSERS

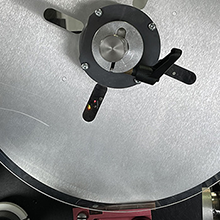

Make hand labeling easier with a label dispenser. Dispense labels up to 5.9" (150mm) wide with any of the models available. Label roll sizes of 7.87" (200mm) OD are accommodated on the standard models with the XL model handling label rolls up to 11.81" (300mm). ECLIPSE MINI PLUS LABEL FINISHING SYSTEM

ECLIPSE MINI PLUS LABEL FINISHING SYSTEM

The Eclipse Mini Plus system is a compact, digital die-cutting and laminating system. This ultra narrow web unit can convert your printed label stock into eye catching, durable labels with custom shapes and finshes. Combine this system with an Epson® ColorWorks® printer and ACU1 accumulator to create a complete compact label creation system.Learn More...

ECLIPSE LF220HS LABEL FINISHING SYSTEM

ECLIPSE LF220HS LABEL FINISHING SYSTEM

Cut your labels faster - at up to 8.5m/min - with the LF220HS High Speed Label Finishing system. This economical space saving model has a small footprint developed to sit neatly in the corner of the factory or workshop on a sturdy bench. It is an accurate and precision engineered, designed to handle large bulk label orders and short runs. This benchtop finisher can also be combined with an Epson® ColorWorks® label printer and 4 station ACU4 accumulator to create a powerful label creation system.Learn more...