FOX IV's design experience, software expertise, and manufacturing capabilities were key in designing a print and apply system to fit into an existing package processing station.

The Challenge and Solution

An integrator was looking to replace obsolete label print and apply systems within an established package handling framework. The total project was to replace over 100 existing systems.

APPLICATION

The system needed to be able to print and apply shipping labels up to 4” x 6” onto packages. The packages ranged in height from 2.625” to 13.25” tall. Labels needed to be applied at a maximum rate of 25 packages per minute. The system required a small label print and apply footprint to fit into the existing handling system frame, the use a 12” OD label roll, and all-electric operation.

ENVIRONMENT/SPECIAL CONDITIONS

Temperature controlled factory environment. Print and apply mounted into an existing design steel frame on the processing station. The all-electric applicator assembly prints and applies to variable height packages within a 10.625” variance. Packages may be overfilled, so the application surface is not always flat.

Implementation and Results

SOLUTION

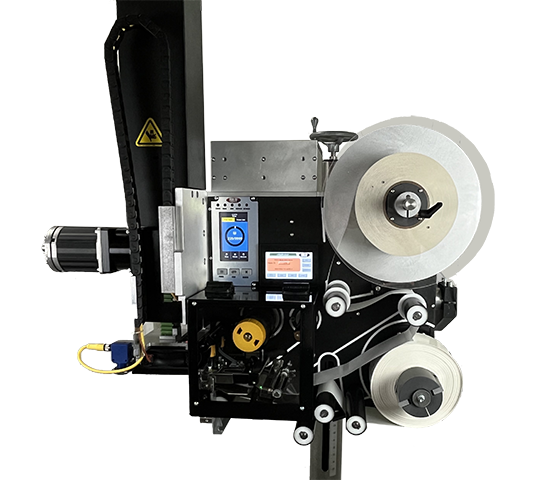

FOX IV designed and manufactured their model E5911M3 Label Print and Apply system with PLC applicator control system with an electric tamp applicator capable of applying to variable package heights. Due to its compact size, the E5911 fit into the existing framework while the Allen-Bradley PLC control enabled easy integration into the existing system.A new electric cylinder with a custom 3D printed soft tamp application pad was designed to accommodate the variable height of the packages as well as their uneven surfaces. This custom design was able to print and apply up to 30 labels per minute within the 2.625” to 13.25” height range, exceeding the customer’s specification. Additionally, the soft pad material provided an additional level of safety for operators.

Adjustments to the label code were made by FOX IV’s software engineers to enable the E5911 to correctly print the shipping label format.

EQUIPMENT PROVIDED

E5911M-3 Label Print and Apply System with:

- Compact design to fit into the existing frame

- Zebra printing technology - 4" print width

- 3” ID x 12” OD Label Roll

- 300 dpi print head

- All-electric Applicator Assembly

- Allen-Bradley PLC Control

- I/O signals to communicate equipment status

- Label-on-pad sensor

- High-speed variable height option

- Custom soft applicator pad

SERVICES PROVIDED

- Engineering design

- Software coding

- Equipment design and manufacturing