Petro-Chemical/Drum

Discover FOX IV solutions for the Petro-Chemical, Ingredient, Feed, and other industries that utilize drums, pails, and tubs.

Drum, Pail, and Tub Labeling

Drum, pail, and large cylindrical applications like feed tubs can be challenging. FOX IV has successfully designed systems for all of these types of applicaitons.

Application Examples

- 55 Gallon Drum Side

- Palleted Drums

- Drum/Pail Top and Sides

- Tapered Tubs/Pails

Learn More

|

FOX IV - Tapered Tub Labeling |

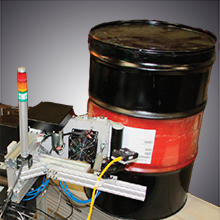

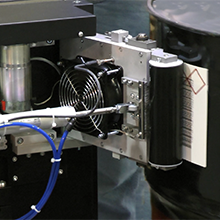

| Features and Benefits • Ability to print and apply a large 6 " x 10" label • 300 dpi print resolution for clear, concise print • Ethernet connectivity • Tilt vacuum belt applicator design for accurate label application FOX IV's expertise in drum and tub labeling along with their ability and experience with large label print and apply enabled FOX IV to provide the end user with a perfect solution to complete the automation of their production line. |

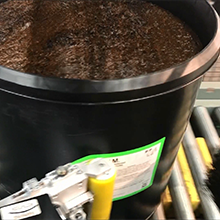

FOX IV's 6956L3 Prints and Applies a large 6" W x 10" L label to tubs. Printing & Applying a Large Label on a Tapered Tub BACKGROUND: A bulk feed producer needed to incorporate label print and apply to complete the automation of their packaging line. Previously, labels were printed on a desk top label printer in batches by LOT and specific formulation. The labels were then hand applied to each tub. The balance of the line incorporated robotics to seal each tub and palletize them. APPLICATION: The end-user needed to have a 6"W x 10"L label applied to their tapered feed tubs as they were moving on a conveyor travelling at 60 fpm. The tubs were 19 1/4" tall with a 3.7 degree taper ranging from a 21" diameter at the top of the tub to a 19 3/4" diameter at the bottom of the tub. Labels needed to be applied at a maximum rate of 4 per minute. The end-user required high quality print due to the amount of label information and certification symbols. They also requested Ethernet connectivity for data streaming to the labeling equipment from their system. ENVIRONMENT/SPECIAL CONDITIONS: Temperature controlled factory environment. Print and apply mounted along existing conveyor line prior to robotic intervention. SOLUTION: FOX IV provided a 6956L3 Print and Apply system with PLC applicator control system, Ethernet connectivity, and a 300 dpi print engine. The 6956L3 was mounted directly on the conveyor line upstream from two industrial robots - one that placed the lid on each tub and one that removed the tub from the conveyor line and placed it on a pallet. The FOX IV 6956L3 printed each label as the tub entered the labeling station. Label application was triggered from a retroreflective photosensor mounted to the conveyor. The print and apply labeler featured a tilting vacuum belt applicator assembly to cleanly position and apply the large 6" x 10" label to the tapered tub. A supplemental application brush ensured the labels were adhered well. The addition of the FOX IV 6956L3 Print and Apply system eliminated the customer hand labeling, increased efficiency, and reduced misplaced or crooked labels on the product. EQUIPMENT PROVIDED 6956L3 Print and Apply System with

SERVICES PROVIDED: On-site installation and training |

| FOX IV TECHNOLOGIES, INC 6011 Enterprise Drive, Export, PA 15632 724-387-3500 sales@foxiv.com www.foxiv.com |

| VIDEO URL: https://youtu.be/U1Ihp5Cc5_E |